1 室内检测方法

表1 常见的氢陷阱及其激活能

Table 1 Common hydrogen traps and their trapping energies

是针尖的功函数,

是针尖的功函数, 是样品的功函数,e是电子的电荷,Vtip是探针的电势,Vsample是试样的电势,CPD为接触电势差。

是样品的功函数,e是电子的电荷,Vtip是探针的电势,Vsample是试样的电势,CPD为接触电势差。

2 现场检测方法

表2 氢通量仪参数

Table 2 Parameter of hydrogen flux method

表3 氢探针参数

Table 3 Parameter of hydrogen probe method

选择氢探针类型时,要根据管道或设备的运行压力、安装位置、是否易于拆卸等因素综合考虑。

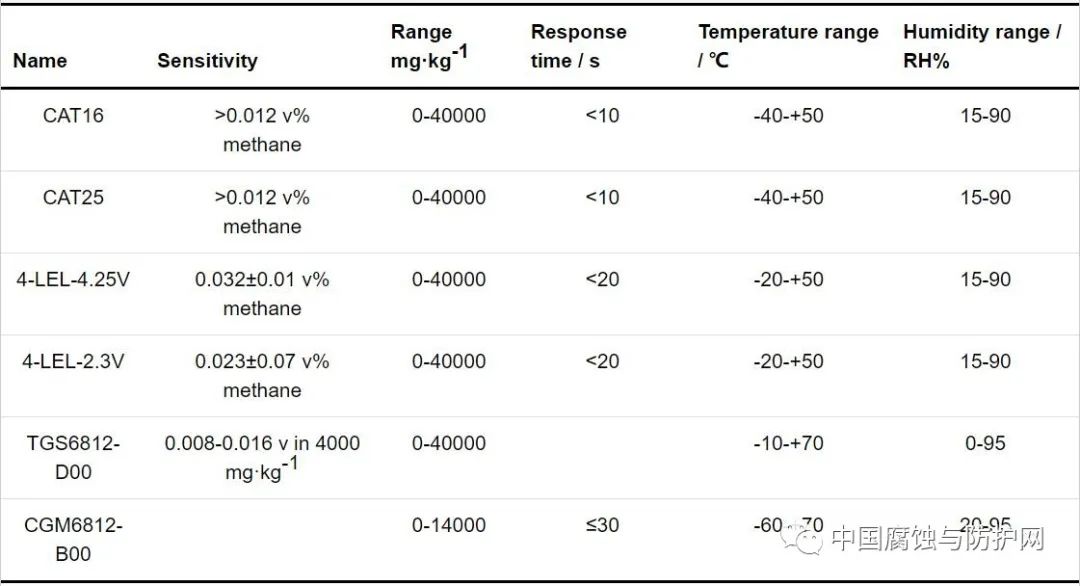

表4 催化氢传感器参数

Table 4 Parameter of catalytic hydrogen sensor

表5 电流型氢传感器参数

Table 5 Parameter of electrical current hydrogen sensor

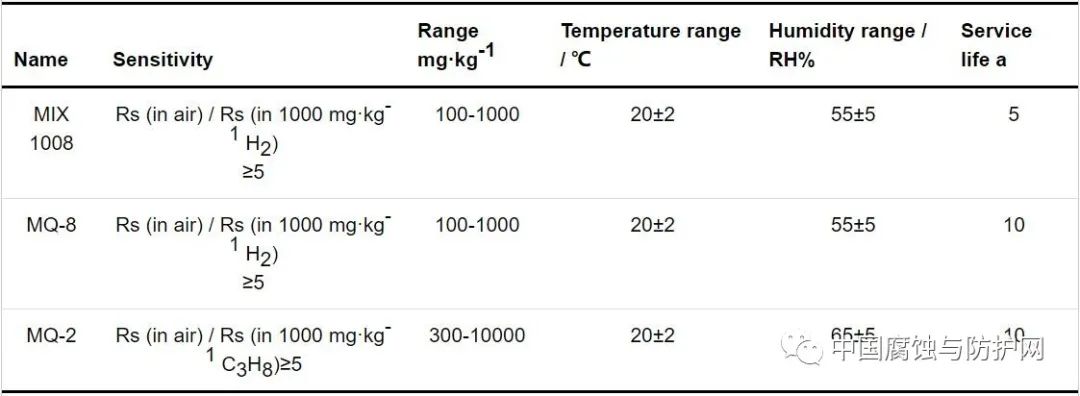

表6 半导体金属氧化物氢传感器

Table 6 Parameter of semiconducting metal–oxide hydrogen sensor

3 总结和展望

参考文献

[1]Zhang Z, Zhao Y J, Cai N.Technological development status and prospect of hydrogen energy industry in China[J]. Nat. Gas Ind., 2022, 42(5): 156[本文引用: 1]张 智, 赵苑瑾, 蔡 楠.中国氢能产业技术发展现状及未来展望[J]. 天然气工业, 2022, 42(5): 156[本文引用: 1]

[2]Han H M, Yang Z, Wang M, et al.The current situation and prospect of hydrogen production and utilization in China[J]. China Coal, 2021, 47(5): 59[本文引用: 1]韩红梅, 杨 铮, 王 敏 等.我国氢气生产和利用现状及展望[J]. 中国煤炭, 2021, 47(5): 59[本文引用: 1]

[3]Liu J, Zhong C F.Current status and prospects of hydrogen energy development in China[J]. China Energy, 2019, 41(2): 32[本文引用: 1]刘 坚, 钟财富.我国氢能发展现状与前景展望[J]. 中国能源, 2019, 41(2): 32[本文引用: 1]

[4]Yang J, Wang X L, Li Z Z, et al.Present status and discussion of long-distance pipeline hydrogen transportation technology[J]. Pressure Vessel Technol., 2021, 38(2): 80[本文引用: 1]杨 静, 王晓霖, 李遵照 等.氢气长距离管输技术现状与探讨[J]. 压力容器, 2021, 38(2): 80[本文引用: 1]

[5]Ma T X, Gao L Z, Hu M J, et al.Research progress of solid hydrogen storage materials[J]. J. Funct. Mater., 2018, 49: 4001DOI [本文引用: 1] 马通祥, 高雷章, 胡蒙均 等.固体储氢材料研究进展[J]. 功能材料, 2018, 49: 4001DOI [本文引用: 1]

[6]Shang J, Lu Y H, Zheng J Y, et al.Research status-in-situ and key challenges in pipeline transportation of hydrogen-natural gas mixtures[J]. Chem. Ind. Eng. Prog., 2021, 40: 5499[本文引用: 1]尚 娟, 鲁仰辉, 郑津洋 等.掺氢天然气管道输送研究进展和挑战[J]. 化工进展, 2021, 40: 5499[本文引用: 1]

[7]Li J F, Su Y, Zhang H, et al.Research progresses on pipeline transportation of hydrogen-blended natural gas[J]. Nat. Gas Ind., 2021, 41(4): 137[本文引用: 1]李敬法, 苏 越, 张 衡 等.掺氢天然气管道输送研究进展[J]. 天然气工业, 2021, 41(4): 137[本文引用: 1]

[8]McBreen J, Nonis L, Beck W.A method for determination of the permeation rate of hydrogen through metal membranes[J]. J. Electrochem. Soc., 1966, 113: 1218DOI URL [本文引用: 1]

[9]Mohtadi-Bonab M A, Karimdadashi R, Eskandari M, et al.Hydrogen-induced cracking assessment in pipeline steels through permeation and crystallographic texture measurements[J]. J. Mater. Eng. Perform., 2016, 25: 1781DOI URL [本文引用: 1]

[10]Xue H B, Cheng Y F.Hydrogen permeation and electrochemical corrosion behavior of the X80 pipeline steel weld[J]. J. Mater. Eng. Perform., 2013, 22: 170DOI URL [本文引用: 1]

[11]Zhang L, Shen H J, Lu K D, et al.Investigation of hydrogen concentration and hydrogen damage on API X80 steel surface under cathodic overprotection[J]. Int. J. Hydrog. Energy, 2017, 42: 29888DOI URL [本文引用: 1]

[12]Zhao W M, Zhang T M, He Z R, et al.Determination of the critical plastic strain-induced stress of X80 steel through an electrochemical hydrogen permeation method[J]. Electrochim. Acta, 2016, 214: 336DOI URL [本文引用: 2]

[13]Sun Y H, Cheng Y F.Hydrogen permeation and distribution at a high-strength X80 steel weld under stressing conditions and the implication on pipeline failure[J]. Int. J. Hydrog. Energy, 2021, 46: 23100DOI URL [本文引用: 1]

[14]Yu Q, Huang Y L, Zheng C B.Hydrogen permeation and corrosion behaviour of high strength steel 35CrMo under cyclic wet-dry conditions[J]. Corros. Eng. Sci. Technol., 2008, 43: 241DOI URL [本文引用: 1]

[15]Liu S G, Zhou Y, Wang Z, et al.Progress of detection techniques for hydrogen mapping in steel[J]. Surf. Technol., 2020, 49(8): 1[本文引用: 2]刘神光, 周 耀, 王 正 等.钢中氢分布检测技术进展[J]. 表面技术, 2020, 49(8): 1[本文引用: 2]

[16]Depover T, Wallaert E, Verbeken K.On the synergy of diffusible hydrogen content and hydrogen diffusivity in the mechanical degradation of laboratory cast Fe-C alloys[J]. Mater. Sci. Eng., 2016, 664A: 195[本文引用: 1]

[17]Depover T, Verbeken K.The effect of TiC on the hydrogen induced ductility loss and trapping behavior of Fe-C-Ti alloys[J]. Corros. Sci., 2016, 112: 308DOI URL [本文引用: 1]

[18]Depover T, Verbeken K.Evaluation of the effect of V4C3 precipitates on the hydrogen induced mechanical degradation in Fe-C-V alloys[J]. Mater. Sci. Eng., 2016, 675A: 299

[19]Depover T, Verbeken K.Thermal desorption spectroscopy study of the hydrogen trapping ability of W based precipitates in a Q&T matrix[J]. Int. J. Hydrog. Energy, 2018, 43: 5760DOI URL [本文引用: 1]

[20]Laureys A, Claeys L, Pinson M, et al.Thermal desorption spectroscopy evaluation of hydrogen-induced damage and deformation-induced defects[J]. Mater. Sci. Technol., 2020, 36: 1389DOI URL [本文引用: 1]

[21]Qu W M, Hua Z L, Li X Y, et al.Application of TDS technology in the study of hydrogen traps in the materials of hydrogen storage vessels[J]. Chem. Ind. Eng. Prog., 2017, 36: 4160DOI [本文引用: 2] 屈文敏, 花争立, 李雄鹰 等.热脱附谱技术在储氢容器材料氢陷阱研究中的应用研究进展[J]. 化工进展, 2017, 36: 4160DOI [本文引用: 2]

[22]Tateyama Y, Ohno T.Stability and clusterization of hydrogen-vacancy complexes in α-Fe: an ab initio study[J]. Phys. Rev., 2003, 67B: 174105[本文引用: 1]

[23]Mirzaev D A, Mirzoev A A, Okishev K Y, et al.Hydrogen-vacancy interaction in bcc iron: ab initio calculations and thermodynamics[J]. Mol. Phys., 2014, 112: 1745DOI URL [本文引用: 1]

[24]Lee J L, Lee J Y.Hydrogen trapping in AISI 4340 steel[J]. Met. Sci., 1983, 17: 426DOI URL [本文引用: 2]

[25]Zhao Y, Lu G.QM/MM study of dislocation—hydrogen/helium interactions in α-Fe[J]. Model. Simul. Mater. Sci. Eng., 2011, 19: 065004[本文引用: 1]

[26]Itakura M, Kaburaki H, Yamaguchi M, et al.The effect of hydrogen atoms on the screw dislocation mobility in bcc iron: A first-principles study[J]. Acta Mater., 2013, 61: 6857DOI URL [本文引用: 1]

[27]Choo W Y, Lee J Y.Thermal analysis of trapped hydrogen in pure iron[J]. Metall. Trans., 1982, 13A: 135[本文引用: 2]

[28]Hagi H, Hayashi Y.Effect of dislocation trapping on hydrogen and deuterium diffusion in iron[J]. Trans. Jpn. Inst. Met., 1987, 28: 368DOI URL [本文引用: 1]

[29]Takai K, Homma Y, Izutsu K, et al.Identification of trapping sites in high-strength steels by secondary ion mass spectrometry for thermally desorbed hydrogen[J]. J. Jpn. Inst. Met. Mater., 1996, 60: 1155[本文引用: 1]

[30]Bernstein I M.The effect of hydrogen on the deformation of iron[J]. Scr. Metall., 1974, 8: 343DOI URL [本文引用: 1]

[31]Lin Y C, Chen D, Chiang M H, et al.Response of hydrogen desorption and hydrogen embrittlement to precipitation of nanometer-sized copper in tempered martensitic low-carbon steel[J]. JOM, 2019, 71: 1349DOI [本文引用: 1]

[32]Parvathavarthini N, Saroja S, Dayal R K, et al.Studies on hydrogen permeability of 2.25% Cr-1% Mo ferritic steel: correlation with microstructure[J]. J. Nucl. Mater., 2001, 288: 187DOI URL [本文引用: 1]

[33]Turnbull A, Hutchings R B.Analysis of hydrogen atom transport in a two-phase alloy[J]. Mater. Sci. Eng., 1994, 177A: 161[本文引用: 1]

[34]Yagodzinskyy Y, Todoshchenko O, Papula S, et al.Hydrogen solubility and diffusion in austenitic stainless steels studied with thermal desorption spectroscopy[J]. Steel Res. Int., 2011, 82: 20DOI URL [本文引用: 1]

[35]Yamabe J, Yoshikawa M, Matsunaga H, et al.Hydrogen trapping and fatigue crack growth property of low-carbon steel in hydrogen-gas environment[J]. Int. J. Fatigue, 2017, 102: 202DOI URL [本文引用: 1]

[36]Samanta S, Kumari P, Mondal K, et al.An alternative and comprehensive approach to estimate trapped hydrogen in steels using electrochemical permeation tests[J]. Int. J. Hydrog. Energy, 2020, 45: 26666DOI URL [本文引用: 1]

[37]Pérez T E, García J O.Direct observation of hydrogen evolution in the electron microscope scale[J]. Scr. Metall., 1982, 16: 161DOI URL [本文引用: 1]

[38]Ichitani K, Kanno M.Visualization of hydrogen diffusion in steels by high sensitivity hydrogen microprint technique[J]. Sci. Technol. Adv. Mater., 2003, 4: 545DOI URL [本文引用: 1]

[39]Sundararajan T, Akiyama E, Tsuzaki K.Hydrogen mapping across crevices[J]. Electrochem. Solid-State Lett., 2005, 8: B30DOI URL [本文引用: 1]

[40]Ohmisawa T, Uchiyama S, Nagumo M.Detection of hydrogen trap distribution in steel using a microprint technique[J]. J. Alloy. Compd., 2003, 356/357: 290[本文引用: 1]

[41]Ishikawa N, Sueyoshi H, Nagao A.Hydrogen microprint analysis on the effect of dislocations on grain boundary hydrogen distribution in steels[J]. ISIJ Int., 2016, 56: 413DOI URL [本文引用: 1]

[42]Jack T A, Pourazizi R, Ohaeri E, et al.Investigation of the hydrogen induced cracking behaviour of API 5L X65 pipeline steel[J]. Int. J. Hydrog. Energy, 2020, 45: 17671DOI URL [本文引用: 2]

[43]Thomas A, Szpunar J A.Hydrogen diffusion and trapping in X70 pipeline steel[J]. Int. J. Hydrog. Energy, 2020, 45: 2390DOI URL [本文引用: 1]

[44]Mohtadi-Bonab M A, Szpunar J A, Razavi-Tousi S S.A comparative study of hydrogen induced cracking behavior in API 5L X60 and X70 pipeline steels[J]. Eng. Fail. Anal., 2013, 33: 163DOI URL [本文引用: 1]

[45]Koyama M, Yamasaki D, Nagashima T, et al.In situ observations of silver-decoration evolution under hydrogen permeation: effects of grain boundary misorientation on hydrogen flux in pure iron[J]. Scr. Mater., 2017, 129: 48DOI URL [本文引用: 1]

[46]Koyama M, Rohwerder M, Tasan C C, et al.Recent progress in microstructural hydrogen mapping in steels: quantification, kinetic analysis, and multi-scale characterisation[J]. Mater. Sci. Technol., 2017, 33: 1481DOI URL [本文引用: 2]

[47]Gu C H, Zhu S Y, Zheng J Y, et al.Measurement of local hydrogen distribution in metals based on scanning kelvin probe force microscope[J]. Surf. Technol., 2019, 48(10): 329[本文引用: 3]顾超华, 朱盛依, 郑津洋 等.基于扫描开尔文探针力显微镜的金属中局部氢分布测试方法研究[J]. 表面技术, 2019, 48(10): 329[本文引用: 3]

[48]Wang G, Yan Y, Yang X N, et al.Investigation of hydrogen evolution and enrichment by scanning Kelvin probe force microscopy[J]. Electrochem. Commun., 2013, 35: 100DOI URL [本文引用: 2]

[49]Hua Z L, An B, Iijima T, et al.The finding of crystallographic orientation dependence of hydrogen diffusion in austenitic stainless steel by scanning Kelvin probe force microscopy[J]. Scr. Mater., 2017, 131: 47DOI URL [本文引用: 1]

[50]Hua Z L, Zhu S Y, Shang J, et al.Scanning Kelvin probe force microscopy study on hydrogen distribution in austenitic stainless steel after martensitic transformation[J]. Mater. Lett., 2019, 245: 41DOI URL [本文引用: 1]

[51]Hua Z L, Wang D L, Liu Z L, et al.Hydrogen distribution at twin boundary in austenitic stainless steel studied by scanning Kelvin probe force microscopy[J]. Mater. Lett., 2019, 234: 175DOI URL [本文引用: 1]

[52]Li M, Guo L Q, Qiao L J, et al.The mechanism of hydrogen-induced pitting corrosion in duplex stainless steel studied by SKPFM[J]. Corros. Sci., 2012, 60: 76DOI URL [本文引用: 1]

[53]Senöz C, Evers S, Stratmann M, et al.Scanning Kelvin probe as a highly sensitive tool for detecting hydrogen permeation with high local resolution[J]. Electrochem. Commun., 2011, 13: 1542DOI URL [本文引用: 1]

[54]Zhu Z W, Hou J, Zheng T, et al.Development of secondary ion mass spectrometry[J]. J. South-Central Univ. Nationalities (Nat. Sci. Ed.), 2011, 30: 67[本文引用: 1]祝兆文, 侯 杰, 郑 涛 等.二次离子质谱进展[J]. 中南民族大学学报 (自然科学版), 2011, 30: 67[本文引用: 1]

[55]Li H Y, Niu R M, Li W, et al.Hydrogen in pipeline steels: recent advances in characterization and embrittlement mitigation[J]. J. Nat. Gas Sci. Eng., 2022, 105: 104709DOI URL [本文引用: 2]

[56]Sobol O, Holzlechner G, Nolze G, et al.Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) imaging of deuterium assisted cracking in a 2205 duplex stainless steel micro-structure[J]. Mater. Sci. Eng., 2016, 676A: 271[本文引用: 1]

[57]Röhsler A, Sobol O, Hänninen H, et al.In-situ ToF-SIMS analyses of deuterium re-distribution in austenitic steel AISI 304L under mechanical load[J]. Sci. Rep., 2020, 10: 3611DOI PMID [本文引用: 1]

[58]Takai K, Seki J, Homma Y.Observation of trapping sites of hydrogen and deuterium in high-strength steels by using secondary ion mass spectrometry[J]. Mater. Trans., JIM, 1995, 36: 1134[本文引用: 1]

[59]Awane T, Fukushima Y, Matsuo T, et al.Highly sensitive detection of net hydrogen charged into austenitic stainless steel with secondary ion mass spectrometry[J]. Anal. Chem., 2011, 83: 2667DOI PMID [本文引用: 2]

[60]Sobol O, Holzlechner G, Holzweber M, et al.First use of data fusion and multivariate analysis of ToF-SIMS and SEM image data for studying deuterium-assisted degradation processes in duplex steels[J]. Surf. Interface Anal., 2016, 48: 474DOI URL [本文引用: 1]

[61]Liu W Q, Liu Q D, Gu J F.Development and application of atom probe tomography[J]. Acta Metall. Sin., 2013, 49: 1025DOI [本文引用: 1] 刘文庆, 刘庆冬, 顾剑锋.原子探针层析技术(APT) 最新进展及应用[J]. 金属学报, 2013, 49: 1025DOI [本文引用: 1]

[62]Shen Q, Wang Z M, Li H, et al.Effects of voltage and laser modes on test results of three-dimensional atom probe[J]. PTCA (Part A: Phys. Test.), 2018, 54: 385[本文引用: 1]沈 琴, 王泽民, 李 慧 等.电压和激光模式对三维原子探针测试结果的影响[J]. 理化检验: 物理分册, 2018, 54: 385[本文引用: 1]

[63]Li L F, Song B, Cheng J, et al.Effects of vanadium precipitates on hydrogen trapping efficiency and hydrogen induced cracking resistance in X80 pipeline steel[J]. Int. J. Hydrog. Energy, 2018, 43: 17353DOI URL [本文引用: 1]

[64]Takahashi J, Kawakami K, Kobayashi Y, et al.The first direct observation of hydrogen trapping sites in TiC precipitation-hardening steel through atom probe tomography[J]. Scr. Mater., 2010, 63: 261DOI URL [本文引用: 1]

[65]Takahashi J, Kawakami K, Tarui T.Direct observation of hydro-gen-trapping sites in vanadium carbide precipitation steel by atom probe tomography[J]. Scr. Mater., 2012, 67: 213DOI URL [本文引用: 1]

[66]Takahashi J, Kawakami K, Kobayashi Y.Origin of hydrogen trapping site in vanadium carbide precipitation strengthening steel[J]. Acta Mater., 2018, 153: 193DOI URL [本文引用: 1]

[67]Stephenson L T, Szczepaniak A, Mouton I, et al.The Laplace Project: An integrated suite for preparing and transferring atom probe samples under cryogenic and UHV conditions[J]. PLoS One, 2018, 13: e0209211DOI URL [本文引用: 1]

[68]Dabah E, Griesche A, Beyer K, et al. In situ measurements of hydrogen diffusion in duplex stainless steels by neutron radiography [A]. KannengiesserT, BabuS S, KomizoY I, et al.In-situ Studies with Photons, Neutrons and Electrons Scattering II[M]. Cham: Springer, 2014: 155[本文引用: 2]

[69]Beyer K, Kannengiesser T, Griesche A, et al.Neutron radiography study of hydrogen desorption in technical iron[J]. J. Mater. Sci., 2011, 46: 5171DOI URL [本文引用: 1]

[70]Griesche A, Dabah E, Kannengiesser T, et al.Three-dimensional imaging of hydrogen blister in iron with neutron tomography[J]. Acta Mater., 2014, 78: 14DOI URL [本文引用: 2]

[71]Beyer K, Kannengiesser T, Griesche A, et al.Study of hydrogen effusion in austenitic stainless steel by time-resolved in-situ measurements using neutron radiography[J]. Nucl. Instrum. Met. Phys. Res. Sect., 2011, 651: 211[本文引用: 1]

[72]Ajito S, Hojo T, Koyama M, et al.Application of an iridium complex for detecting hydrogen permeation through pure iron[J]. Int. J. Hydrog. Energy, 2020, 45: 25580DOI URL [本文引用: 1]

[73]Stejskal J, Kratochvíl P, Jenkins A D.The formation of polyaniline and the nature of its structures[J]. Polymer, 1996, 37: 367DOI URL [本文引用: 1]

[74]Kakinuma H, Ajito S, Hojo T, et al.Real-time visualization of hydrogen distribution in metals using polyaniline: an ultrasensitive hydrogenochromic sensor[J]. Adv. Mater. Interfaces, 2022, 9: 2101984DOI URL [本文引用: 2]

[75]Kakinuma H, Ajito S, Hojo T, et al.Simultaneous observations of the corrosion behavior of an Fe sheet and the associated hydrogen distribution therein employing a hydrogenochromic sensor[J]. Corros. Sci., 2022, 206: 110534DOI URL [本文引用: 1]

[76]Kakinuma H, Ajito S, Hojo T, et al.In situ 2D mapping of hydrogen entry into an Fe sheet under a droplet of NaCl solution using a hydrogenochromic sensor[J]. Int. J. Hydrog. Energy, 2022, 47: 38468DOI URL [本文引用: 1]

[77]Sugawara Y, Sakaizawa Y, Shibata A, et al.Detection of hydrogen distribution in pure iron using WO3 thin film[J]. ISIJ Int., 2018, 58: 1860DOI URL [本文引用: 2]

[78]Sugawara Y, Saito H.Improved responsivity and sensitivity of hydrogen mapping technique in pure iron using WO3 thin film by control of Pd intermediate layer[J]. ISIJ Int., 2021, 61: 1201DOI URL [本文引用: 1]

[79]Liu X L, Zhang D P, Dong Z H, et al.Amperometric hydrogen permeation flux method for online corrosion monitoring of oil and gas pipelines[J]. CIESC J., 2014, 65: 3098DOI [本文引用: 1] 刘向录, 张德平, 董泽华 等.电化学氢通量法用于油气管线在线腐蚀监测[J]. 化工学报, 2014, 65: 3098DOI [本文引用: 1]

[80]Hübert T, Boon-Brett L, Black G, et al.Hydrogen sensors–a review[J]. Sens. Actuators, 2011, 157B: 329[本文引用: 1]

[81]Zhang W, Yu D R, Xu Z Z, et al.Study on temperature compensation of hydrogen sensor in catalytic combustion[J]. Transducer Microsyst. Technol., 2020, 39(8): 62[本文引用: 1]张 巍, 于德润, 徐振忠 等.催化燃烧氢气传感器的温度补偿研究[J]. 传感器与微系统, 2020, 39(8): 62[本文引用: 1]

[82]Li Q R.Research progress of hydrogen sensor[J]. Saf. Health Environ., 2021, 21(9): 14[本文引用: 1]李庆润.氢气传感器研究进展[J]. 安全、健康和环境, 2021, 21(9): 14[本文引用: 1]

[83]Chen X M, Yang G Q, Zhao H R, et al.The application of metal oxide semiconductor gas sensors and their developmen[J]. J. Yuxi Norm. Univ., 2020, 36(6): 57[本文引用: 1]陈祥铭, 杨贵钦, 赵海茹 等.金属氧化物半导体气体传感器应用现状和发展情况[J]. 玉溪师范学院学报, 2020, 36(6): 57[本文引用: 1]

[84]Nazarov A, Vucko F, Thierry D.Scanning Kelvin Probe for detection of the hydrogen induced by atmospheric corrosion of ultra-high strength steel[J]. Electrochim. Acta, 2016, 216: 130DOI URL [本文引用: 1]

[85]Cui Y Y, Fan Y M, Wei J Z, et al.Research progress of cathodic disbonding of coatings on buried steel pipeline[J]. Mater. Prot., 2016, 49(8): 62[本文引用: 1]崔艳雨, 范玥铭, 危金卓 等.埋地钢质管道防腐蚀层阴极剥离作用的研究进展[J]. 材料保护, 2016, 49(8): 62[本文引用: 1]

免责声明:本网站所转载的文字、图片与视频资料版权归原创作者所有,如果涉及侵权,请第一时间联系本网删除。

官方微信

《腐蚀与防护网电子期刊》征订启事

- 投稿联系:编辑部

- 电话:010-62316606

- 邮箱:fsfhzy666@163.com

- 腐蚀与防护网官方QQ群:140808414